Holding Tank Odor Management & Level Monitoring

A complete holding tank system solution to resolve the problems of offensive tank odor and tank level monitoring.

Holding Tank Odor

Most odor control products attempt to mask the smell. Research composting toilets, and you will find that they manage the smell by ventilation and feeding additional biological components to promote bacterial decomposition. These concepts can be applied to a typical marine sanitation to effectively and inexpensively manage holding tank odor. Our holding tank system automatically provides forced ventilation on a regular interval, and you add a special bio-augmentation treatment after each pump out to supplement the natural biological processes. Enzyme-loaded products are known as bio-augmentation treatments, because they supplement the natural biological processes.

The bio-autmentation treatment consists of a dry powder that is mixed with water, stored in any plastic container, and then added to the holding tank via the toilet. You can read more about bio-autmentation treatments by reviewing this article by Practical Sailor: Stopping Holding-tank Odors Part II. In the earlier artical, it is stated that "PS prefers the enzyme and biological (bacterial) tank treatments" over cleaning and odor masking products.

Tank Level Monitoring

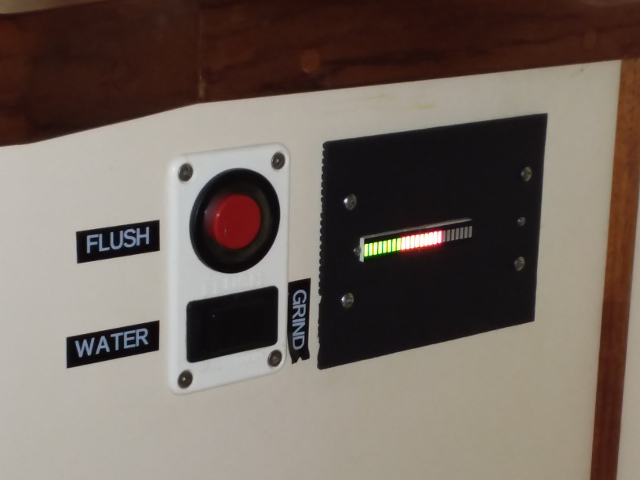

Most level monitoring systems report out only three level readings: 'empty', 'mid', and 'full'. Our system provides a continuous output reading to a display that is easy to understand by anyone onboard.

The level sensor is based on reed switches that approximated a continuous output (industry standard of 240 to 30 ohms). A custom bar LED display is calibrated to be proportional to the sensor position (tank level). Eight LED bars progressively display for each color (green, yellow, and red).

Images of prototype in service since summer 2017:

The prototype utilizes a level sensor with a stainless stem. After a few weeks in the holding tank, corrosion develops on the surface and it must be cleaned. The corrosion is caused primarily by the urine in the tank. Urine consists of primarily of urea, but also chloride, sodium, potassium, and creatinine. Urea is an organic (i.e. carbon-based) compound whose chemical formula is: CON2H4 or (NH2)2CO. It is also known as carbamide. Urea is a non-toxic molecule made of toxic ammonia and carbon dioxide. Urine has a specific gravity between 1.002 and 1.030. Sewage has a specific gravity in the range of 1 to 1.02.

The solution to the sensor stem corrosion problem is to utilize a sensor with a stem and float consisting of a material with strong chemical resistance to urea. The following plastics have high chemical resistance to urea, urine, and sewage: CPVC, PP, PTFE, PVC, PVC-GF, PVDF, EPDM, and FPM.

Preliminary research has identified the following sensors with plastic stem and float:

.jpg)